I still remember the first time I tried to produce a baby romper without a proper tech pack. The factory sent back something that looked more like a potato sack than children’s wear. Since then, one thing has been crystal clear—a good tech pack isn’t optional. It’s the blueprint.

A complete tech pack—which includes technical drawings, measurements, fabric details, and trim specs—is essential for successful manufacturing. It prevents miscommunication, helps maintain sizing consistency, and reduces costly errors during production. It also speeds up sampling, cuts down back-and-forth emails, and builds trust between buyers and suppliers. Whether you're a brand or a factory, clear instructions are everything.

Let’s talk about why skipping the tech pack is like baking a cake without a recipe.

Why is a clear tech pack the foundation of smooth manufacturing?

It’s simple: if you don’t tell the factory exactly what you want, don’t be surprised when you don’t get it. Manufacturers aren’t mind readers. They need specifics.

A clear tech pack ensures your design vision is correctly understood and executed by the factory. It provides the essential “how-to” for every detail of your garment, from neckline width to fabric type to stitching style. Without it, you risk delays, mistakes, and wasted samples.

I like to think of it like building IKEA furniture—imagine trying it with no manual and 300 screws on the floor. That’s what manufacturing feels like without a tech pack.

Dive deeper: What exactly should a tech pack include?

A strong tech pack acts like the universal translator between a designer and the production floor. Here’s what a complete one should have:

- Technical drawings (flat sketches from the front, back, side)

- Bill of materials (BOM): All fabrics, trims, and accessories with codes

- Colorways and fabric details

- Measurement charts by size

- Construction notes: Seams, stitching, special finishes

- Label and packaging guidelines

Let’s take a toddler hoodie as an example.

Without a tech pack:

- You say "soft cotton," the factory uses poly-cotton.

- You picture a 5 cm ribbed cuff, they make it 3 cm.

- You want “relaxed fit,” they send something fitted.

Now multiply that by 500 pieces. That’s not a mistake—that’s a disaster.

| Tech Pack Element | Why It Matters |

|---|---|

| Technical Drawings | Communicates design details visually |

| Fabric Specifications | Ensures correct material is sourced |

| Measurement Chart | Keeps size grading accurate |

| Construction Notes | Guides sewing, hemming, and finish quality |

| Labeling & Packaging Info | Ensures consistent branding and presentation |

When we work with clients at Taian Lianchuang Textile Co., Ltd, we often help them build a tech pack from scratch. Because if the brief is clear, the final product usually is too.

Can detailed specs help avoid costly miscommunication with factories?

Absolutely. I’ve seen how one small misunderstanding can cost weeks—sometimes months.

Detailed specifications eliminate ambiguity between the brand and the factory. They define exactly what’s expected, leaving no room for “guesswork.” That clarity helps reduce sampling rounds, avoids disputes, and keeps production timelines intact.

One buyer once wrote “light blue” in their fabric note. Turns out, “light blue” in China meant baby blue. The buyer wanted dusty blue. We lost two weeks and had to re-source fabric. That one word—light—cost real money.

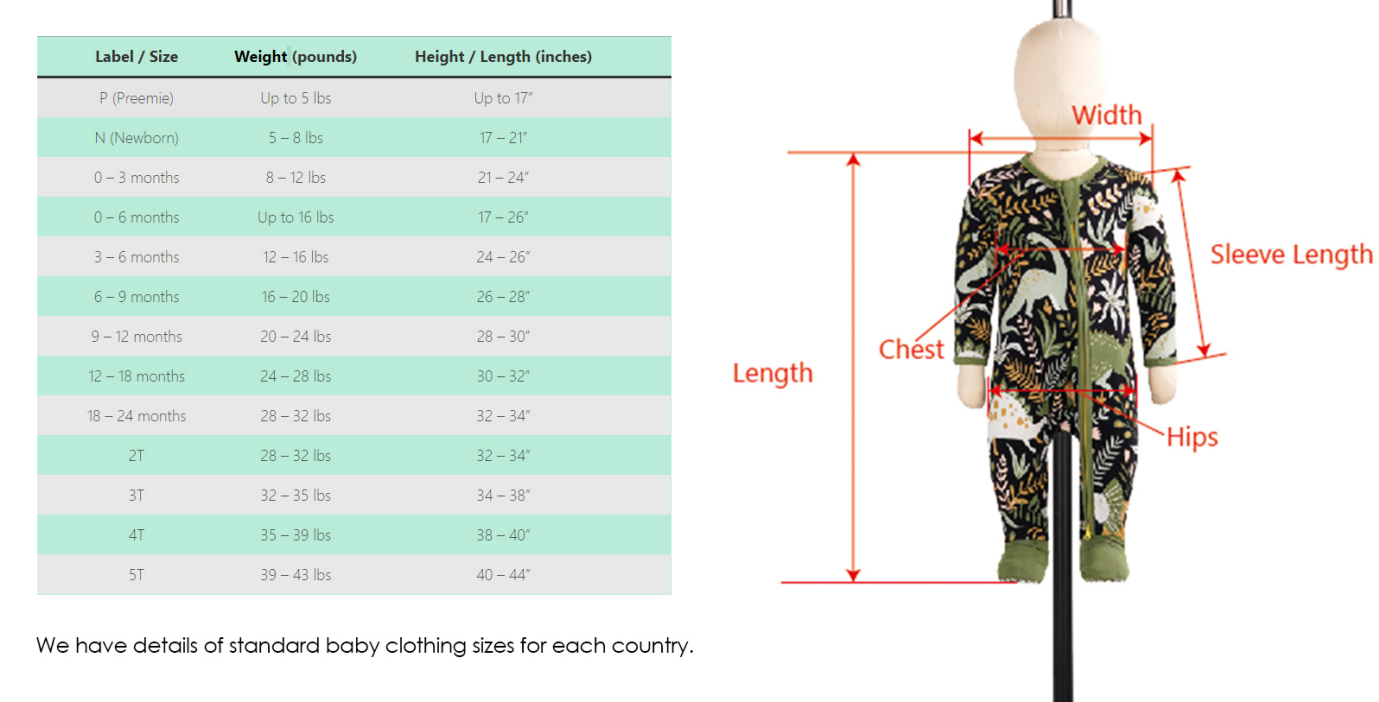

How do accurate measurements ensure consistency across sizes?

When your size 2T fits perfectly, but your size 4T fits like a tent... that’s a grading problem.

Accurate measurement charts in your tech pack ensure that every size is scaled consistently. Factories use these charts to create patterns, so if the numbers are wrong—or missing—the sizing will be too.

It’s not just about width and length. Good charts include:

- Shoulder widths

- Sleeve lengths

- Neckline depths

- Waist elastic relaxed vs. stretched

If you’ve ever had to explain why a kid’s tee was tight in the neck but baggy in the sleeves... yep, that’s a tech pack issue.

Is fabric and trim clarity the key to getting the product we actually want?

Totally. I’ve seen beautiful designs ruined because of poor fabric or trim choices.

Including exact fabric compositions, GSM (weight), and trim details (like zipper type or snap size) ensures the final garment looks, feels, and functions as intended. Even a tiny change in fabric can affect drape, stretch, or comfort—especially in kidswear.

Here’s a real-world story: A buyer wanted soft bamboo jersey for onesies. But the factory swapped it for a cheaper viscose blend. It looked similar but had less stretch—and the neck opening didn’t pass over babies’ heads easily. Parents complained. Orders dropped.

So, we learned: Write it down. And be specific.

| Fabric Detail | Why It Matters |

|---|---|

| Fiber Composition | Impacts softness, stretch, and breathability |

| GSM (grams/sqm) | Affects weight and warmth |

| Dye/Finish | Can cause irritation if not safe or OEKO-TEX-rated |

| Trim Description | Must match safety standards (especially for kids!) |

Does a strong tech pack speed up sampling and production timelines?

Yes—and it's not even close. A clear tech pack means fewer emails, faster samples, and smoother production.

When everything is laid out clearly upfront, factories don’t have to guess or double-check every detail. This leads to quicker sample approval, less back-and-forth, and on-time shipments—which is crucial for hitting sales seasons.

Think about it: If a factory has to stop and ask five questions every time they start a new piece, that time adds up—fast. Especially in B2B.

A strong tech pack = less waiting = fewer delays = happier clients.

Conclusion

Want smoother production, faster samples, and fewer surprises? Build a killer tech pack. It saves time, money, and a lot of stress—for everyone involved.